Save Labor • Save Cost • Keep Up with the Future

Full-Line Smart Packaging Solutions for Various Industries

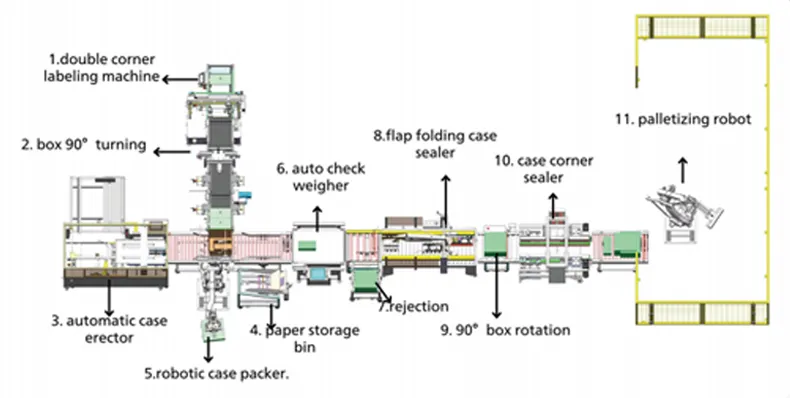

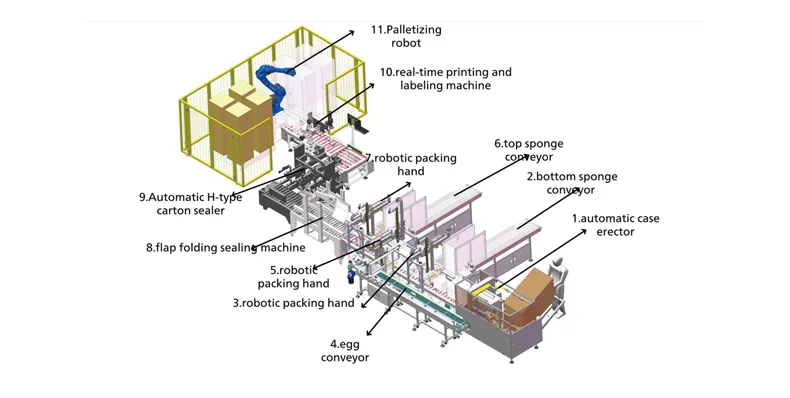

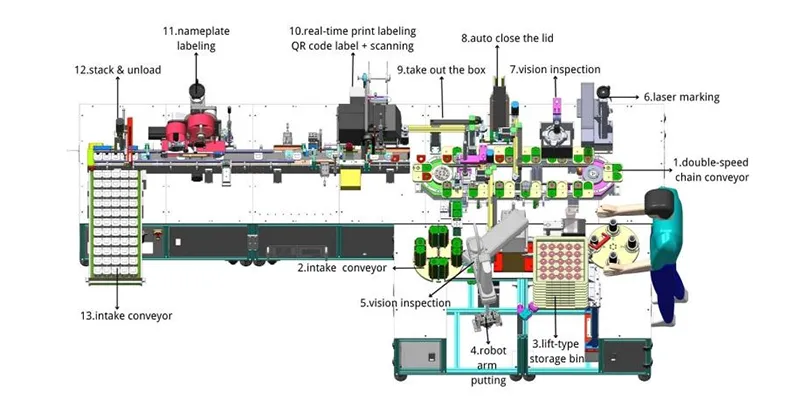

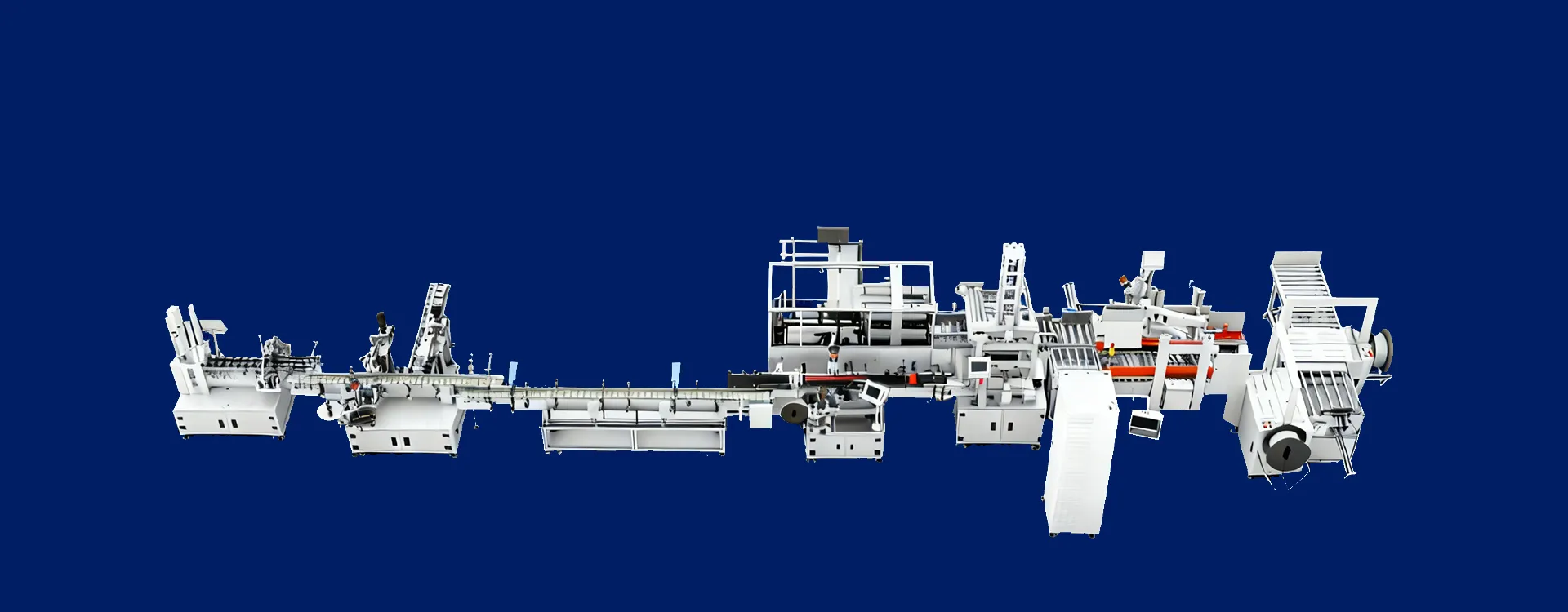

● Product:Folding box(irregular-shaped product) packing line

● Vacuum suction methos fot box loading usding suction cups.

● Real-tomr pringting and labeling with data uploaded to the system.

● Automatic carton forming, auto insertion of product, lid closure and sealing.

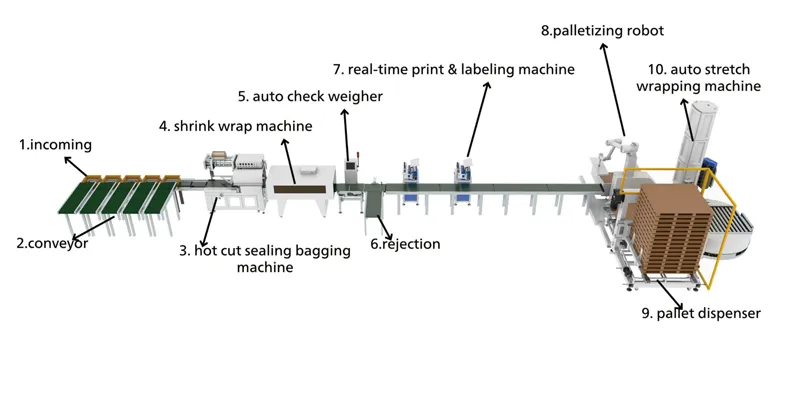

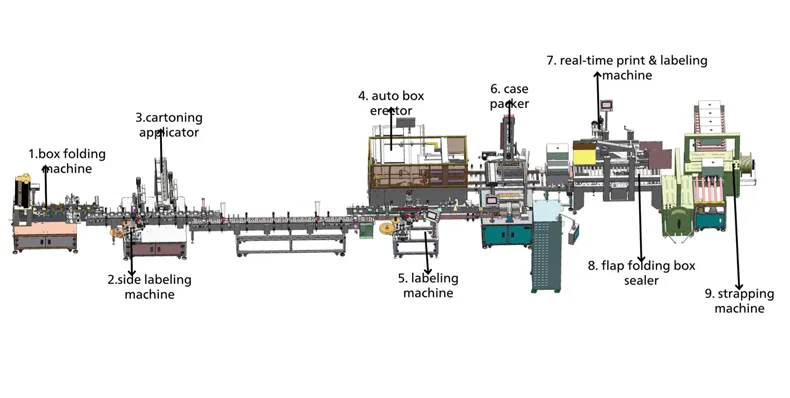

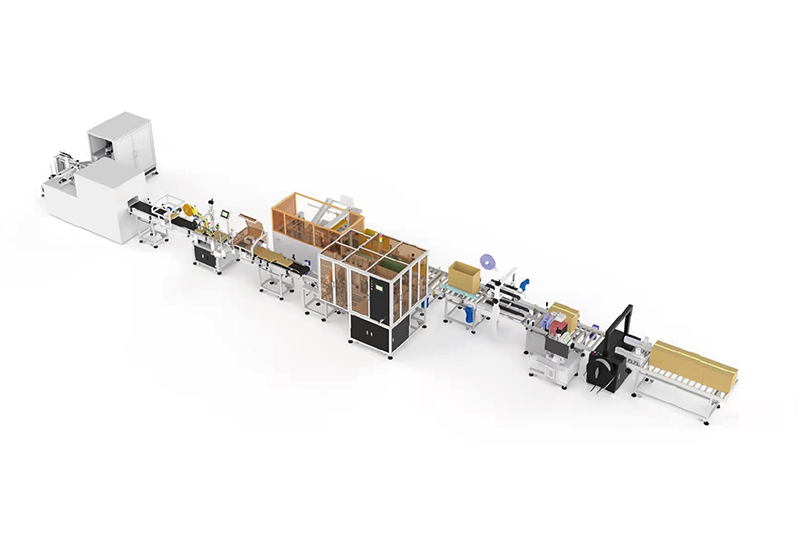

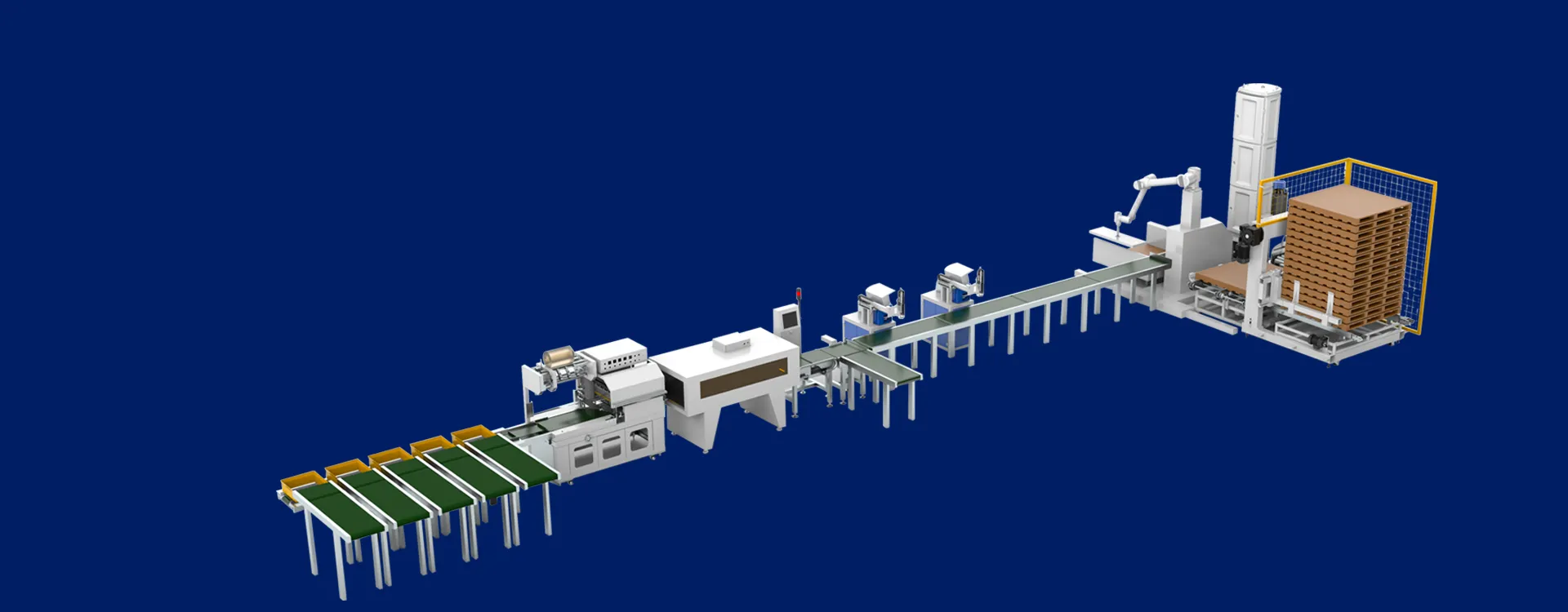

● Product: Book film sealing and shrinking, filmed and shrinked packing product.

● Books enter the automatic film sealing and cutting process.

● Connect to the cartoning machine, and the cartons that have been packed enter the weighing machine.

● Robotic plalletizing

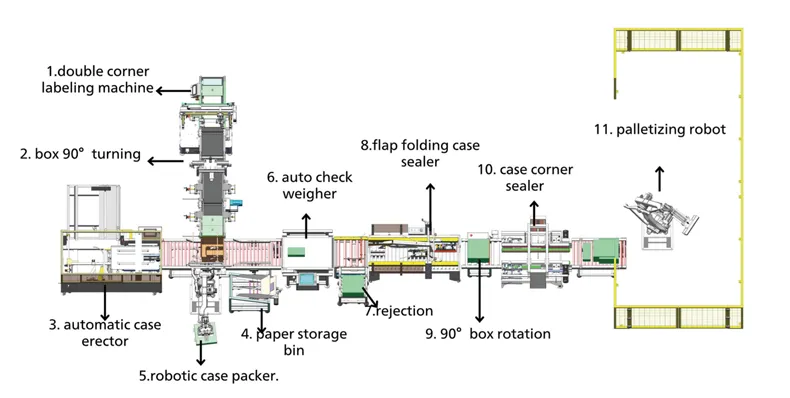

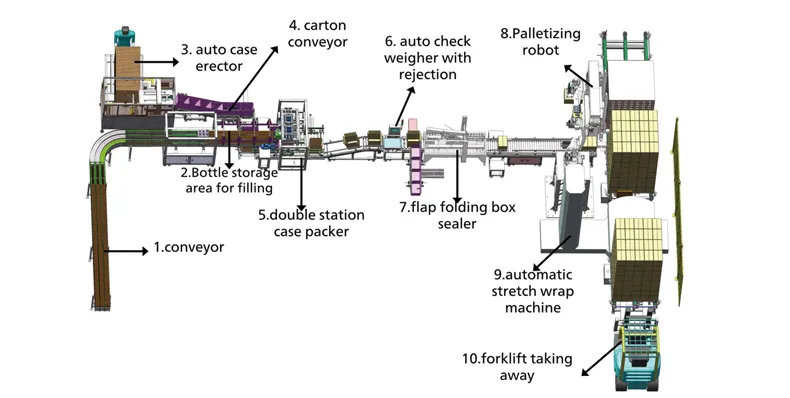

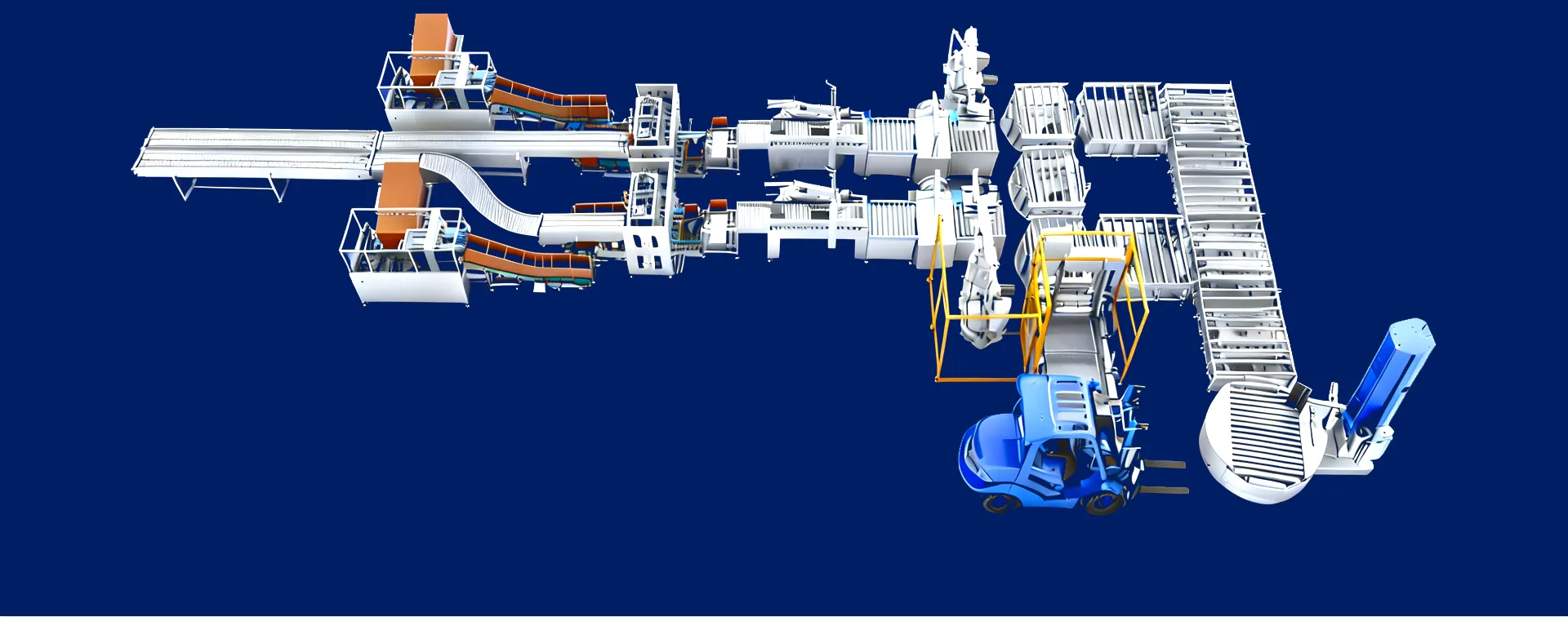

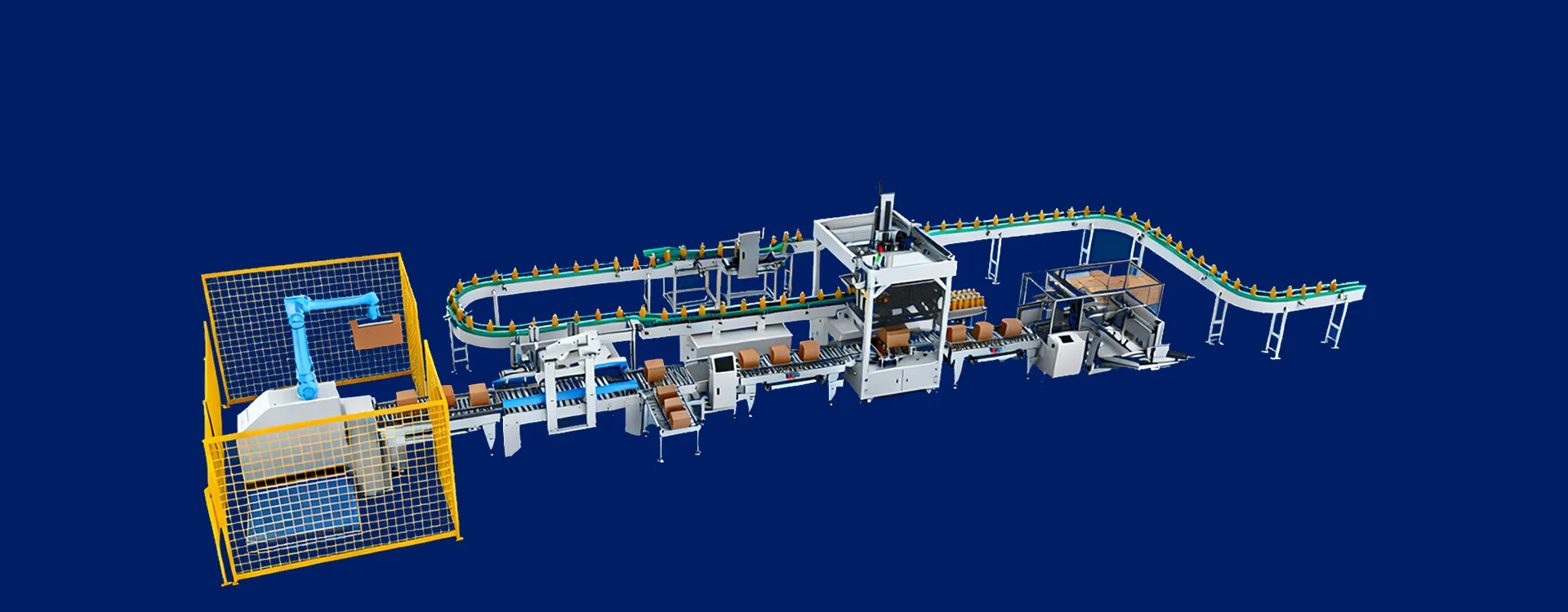

● Product:Glass bottles, bottled products.

● Bottles packed by gripping the bottle caps.

● Connected to the front-end conveyor line.

● Connected to the front-end conveyor line.

Turnkey Packaging Solutions

Integrated packaging lines that deliver higher efficiency, lower labor cost, and consistent performance.

Our Products

One-stop packaging solutions — from automation systems to precision machines.

About JOYDA TECH

Dongguan Joyda Machinery CO.Ltd is a packaging automation manufacturer and system integrator based in China.We design and deliver Industrial 4.0 end-of-line packaging solutions — combining mechanical engineering, automation, and intelligent software.

With our own production workshops and two software companies, we provide both Turnkey Project and standalone machines, covering case packing, bagging, labeling, and Robot Palletizing.

Guided by the principle of “Everything you need in one location,” we integrate design, production, testing, and software control under one system — giving customers one partner, one process, and one reliable result.

Chandra Gour

Graduating from Harvard Business School with a Master's degree in Leadership and Strategy, he possesses extensive professional experience, having held key positions at multiple companies. In 2002, he founded XtraNet Technologies Limited. Over time, the company cultivated a strong workforce and demonstrated its value within the industry by maintaining its position amidst fierce competition.

Why chooce us ?

Integrated Manufacturing & Software Control

Own factory + two software companies — seamless integration of mechanical production and automation control.

Turnkey Project & Flexible Options

One-stop packaging lines or single machines — choose what fits your needs.

Fast Response & Professional Team

With experienced engineers and Harvard-trained consultants, JOYDA can deliver a customized solution proposal within 48 hours.

Smart & Efficient Solutions (Industrial 4.0 + AI)

We design packaging lines with intelligence at the core — combining automation, data connectivity, and predictive control to reduce labor and improve efficiency.

Proven Global Experience

From cartons to books, from food to industrial components — our packaging systems are used in diverse industries across the world.

Everything You Need in One Location · Everything in One

JOYDA provides design, production, testing, and control integration — one partner, one process, one reliable result.

Blog

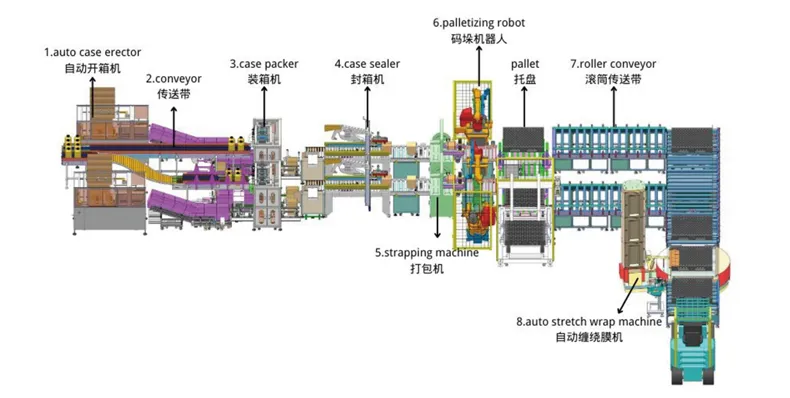

This article explains how a complete packaging line operates as an integrated, perfectly synchronized system. From case erecting and checkweighing through filling, labeling, and sealing, and finally to robotic palletizing and stretch wrapping, every machine plays a vital role in maintaining a smooth production flow.

This article explores how robotic palletizers and automatic stretch wrappers transform end-of-line packaging operations. By automating palletizing and load securing, businesses gain higher throughput, greater accuracy, improved safety, reduced product damage, and a more flexible production setup.

This article outlines how end-of-line automation transforms manual case erecting, sealing, palletizing, and wrapping into a fully streamlined, high-performance workflow. By integrating case erectors, sealers, robotic palletizers, and automatic stretch wrappers, businesses eliminate labor bottlenecks, improve product integrity, reduce material waste, and significantly increase throughput.